Introduction

In the sector of machinery, machinery, and expertise, ensuring that the whole thing runs smoothly is a very powerful. Companies make investments remarkable amounts of time and instruments into keeping their platforms and machinery to avoid pricey downtimes and be sure that safeguard necessities are met. Two critical tactics during this realm are preventive upkeep and calibrations. While they'll seem to be identical in the beginning look, they serve assorted purposes in attaining most well known performance. This article delves deep into the nuances of preventive repairs versus calibrations, shedding faded on their respective roles, importance, and top-rated practices.

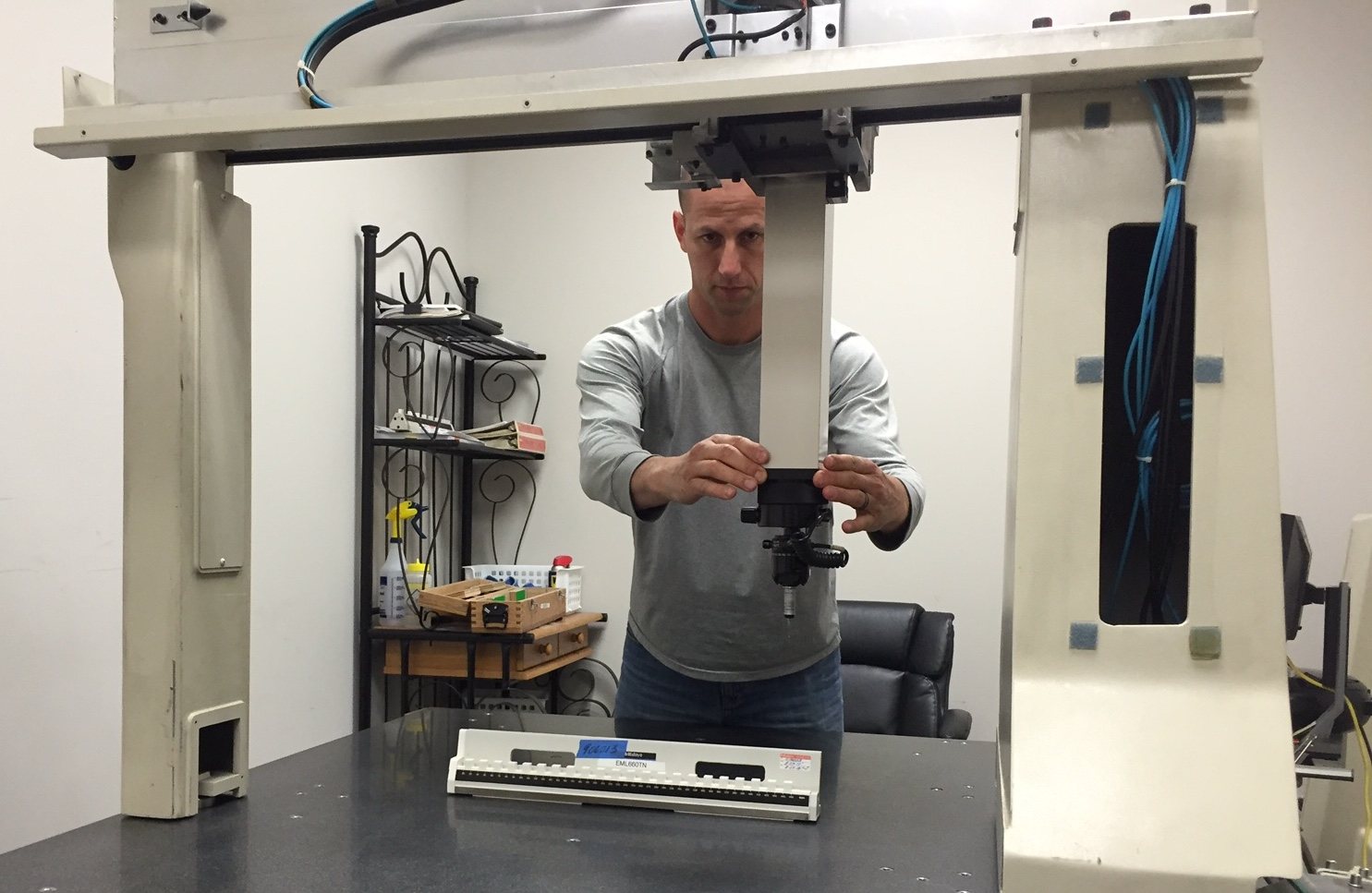

Preventive Maintenance vs Calibrations: Understanding Their Roles

Preventive preservation refers back to the systematic inspection, detection, and correction of advantage failures before they ensue. The commonly used purpose is to keep package in foremost working condition and amplify its lifespan. On the alternative hand, calibration contains adjusting and satisfactory-tuning machine or resources to be sure accuracy in measurements or outputs based on predefined requirements.

Understanding those %%!%%7f895f4d-0.33-47c5-b625-c6fedf6a115a%%!%% processes is significant for organizations striving for operational excellence. When applied adequately, either preventive upkeep and calibrations can radically beef up productiveness whilst minimizing costs related to repairs or inaccuracies.

What is Preventive Maintenance?

Preventive repairs (PM) is a proactive means aimed toward fighting sudden gear mess ups by way of traditional inspections and events duties. It encompasses a vast latitude of pursuits designed to pick out things sooner than they expand into fundamental problems.

Key Objectives of Preventive Maintenance

Minimize Downtime: By typically servicing gadget, organisations can evade unplanned outages. Extend Equipment Life: Consistent care can lengthen the lifespan of machinery. Ensure Safety: Regular exams lend a hand maintain safe practices requirements for employees. Reduce Repair Costs: Addressing minor complications early prevents extra substantial issues.Types of Preventive Maintenance

- Scheduled Maintenance: Regular intervals elegant on time or utilization (e.g., converting oil each and every 3 months). Predictive Maintenance: Uses information prognosis instruments to expect whilst renovation will have to be performed. Condition-Based Maintenance: Involves monitoring the actually circumstance of resources to pick if repairs is wanted.

Importance of Preventive Maintenance

The significance of preventive protection are not able to be overstated:

- Enhanced Operational Efficiency: Well-maintained machines work more suitable and rapid. Cost Savings: Reduced danger of breakdowns results in shrink fix charges. Improved Product Quality: Consistent desktop functionality ensures product pleasant is still high.

What are Calibrations?

Calibration is any other cornerstone in sustaining precise operations inside of quite a lot of industries—noticeably these where precision is needed including pharmaceuticals, production, and engineering.

Defining Calibration

Calibration comprises evaluating an tool's output against a regarded traditional or benchmark. The rationale is to alter the tool so that it produces top results within targeted limits.

Why Calibration Matters

Accuracy Assurance: Ensures that measurements taken through an software are fantastic. Regulatory Compliance: Many industries have strict guidelines requiring calibrated contraptions. Quality Control: Accurate measurements cause larger product high quality. Safety Standards Compliance: Ensures protection devices role as meant.Types of Calibration Techniques

- Static Calibration: Involves measuring recognised values underneath managed conditions. Dynamic Calibration: Tests how tools practice under varying stipulations.

Preventive Maintenance vs Calibrations in Detail

Now that we understand what preventive renovation and calibration entail enable’s delve deeper into their roles inside of plenty of industries.

Industries That Benefit from Preventive Maintenance

Manufacturing Healthcare Transportation Energy ProductionManufacturing Sector

In production, PM plays a pivotal function in maintaining production lines going for walks smoothly:

- Regular preservation schedules keep away from breakdowns that may halt construction. Predictive analytics facilitates manufacturers to foresee knowledge worries founded on old details.

Healthcare Sector

In healthcare settings:

- Medical accessories ought to be maintained carefully due to the influence on sufferer security. Failure to conduct exact PM can lead to excessive outcomes affecting sufferer care.

Industries That Rely on Calibration

Aviation Pharmaceutical Food & Beverage AutomotiveAviation Industry

In aviation:

- Instruments have got to be calibrated accurately for risk-free navigation. Regular calibration assessments verify compliance with stringent law specifications.

Pharmaceutical Sector

For pharmaceuticals:

- Drug efficacy hinges on actual measurements in the time of construction; therefore calibration is integral for compliance with wellness guidelines.

Comparative Analysis

| Aspect | Preventive Maintenance | Calibration | |------------------------|---------------------------------------------------|--------------------------------------------------| | Purpose | To hinder failures in the past they turn up | To make sure accuracy in measurement | | Frequency | Scheduled stylish on time/use | Regularly required via business necessities | | Impact | Enhances durability & performance | Guarantees compliance & product caliber | | Scope | Broader scope overlaying assorted factors | Specific point of interest on measurement gear/tools |

Best Practices for Implementing Preventive Maintenance

Develop a Comprehensive PM Plan:- Identify principal sources requiring primary provider. Establish timelines for inspections based mostly on utilization styles.

- Ensure your group of workers understands PM protocols thoroughly. Encourage reporting any anomalies immediately.

- Implement CMMS (Computerized Maintenance Management System) equipment for monitoring repairs actions efficiently.

- Constantly consider your PM thoughts primarily based on efficiency metrics and adapt as necessary.

Best Practices for Effective Calibration

Schedule Regular Calibration Checks:- Set definite durations for calibration based on utilization intensity or environmental components which can impression accuracy.

- Maintain thorough documents of all calibrations achieved which supports in audits and regulatory compliance verification.

- Ensure in basic terms knowledgeable pros habits calibrations as a result of standardized systems.

- Utilize licensed reference materials (CRM) throughout calibration approaches to guarantee accuracy degrees meet enterprise requisites.

Common Misconceptions about Preventive Maintenance vs Calibrations

Despite their importance, there are a couple of misconceptions surrounding these %%!%%7f895f4d-0.33-47c5-b625-c6fedf6a115a%%!%% practices:

1) PM Is Only About Fixing Things

Many suppose preventive upkeep handiest revolves around fixing damaged things; however it, it’s about improving efficiency by using generic maintenance too!

2) Calibration Is Not Necessary if Equipment Works Fine

Just since an device seems to be purposeful does now not mean it’s imparting actual readings; periodic calibration ensures reliability!

Integration Between Preventive Maintenance and Calibration

While they serve one-of-a-kind applications, integrating preventive repairs with calibration enhances ordinary method reliability:

1) Synergistic Benefits: Regular PM can extend the c programming language among required calibrations by putting forward most popular stipulations for size devices.

2) Streamlined Operations: Combining both practices into a cohesive approach reduces administrative burdens whereas recovering operational effectiveness throughout departments!

Frequently Asked Questions

1) What’s the regularly occurring change between preventive repairs and calibration?

Preventive maintenance focuses on conserving appliance capability even though calibration guarantees dimension accuracy per primary certified pressure transducer calibration principles.

2) How quite often may still I participate in preventive protection?

The frequency relies upon in your actual appliance usage; consult corporation policies or trade ideas for hints adapted in direction of your belongings!

3) Can I bypass preventive protection if my machines look satisfactory?

It’s inadvisable! Even if machines take place practical now skipping PM raises dangers long term breakdowns foremost possibly high priced downtimes later down-the-line!

four) How do I comprehend if my resources desire recalibration?

If you become aware of discrepancies in measured values as compared against generic standards or standards it’s seemingly time for recalibration!

five) Are there prison implications tied up with no longer performing calibrations normally?

Yes! Many industries face strict laws mandating regularly occurring calibrations; failure may want to end in fines or sanctions depending upon jurisdictional authorities in touch!

6) What are a few challenges faced whilst implementing PM & calibration methods readily?

Challenges incorporate resource allocation topics (time/payment), worker practise gaps regarding protocols/systems plus organising an competent tracking machine making certain compliance throughout the time of organization-broad initiatives over timeframes distinct before!

Conclusion

In conclusion, know-how the one-of-a-kind but complementary roles of preventive renovation as opposed to calibrations is foremost for any group trying to optimize its operations and safeguard safeguard standards across its machinery and apparatus portfolios nicely!

While both practices serve distinguished purposes—one that specialize in prolonging asset life at the same time making certain operational efficiency because of habitual care—the alternative ensures precision primary inside countless sectors—the synergy created when these %%!%%7f895f4d-0.33-47c5-b625-c6fedf6a115a%%!%% points intersect in a roundabout way leads organizations towards more suitable productivity levels along decreased operational quotes longer term!

Investing thoroughly into equally components equips businesses not simply in opposition mechanical calibration to unforeseen hindrances yet also paves pathways closer to sustainable development shifting ahead! So no matter if you are answerable for dealing with troublesome production tactics or overseeing certain clinical instrumentation understand—every little bit counts while striving closer to excellence!