Introduction

In the sector of precision and accuracy, regimen apparatus calibrations mechanical calibration play a valuable role. Not only do they make sure that your gadgets offer reputable documents, yet additionally they safety your repute and bottom line. As know-how evolves, the value of calibration becomes even more stated. So, why should always you not ever pass those obligatory approaches? Let’s dive deep into this subject to discover the myriad reasons at the back of asserting strict calibration schedules.

Why You Should Never Skip Routine Equipment Calibrations

Skipping recurring accessories calibrations can cause a cascade of complications that influence high quality, protection, and compliance. When machines and instruments aren’t competently calibrated, they may be able to produce faulty results that would compromise operational integrity.

What Is Calibration?

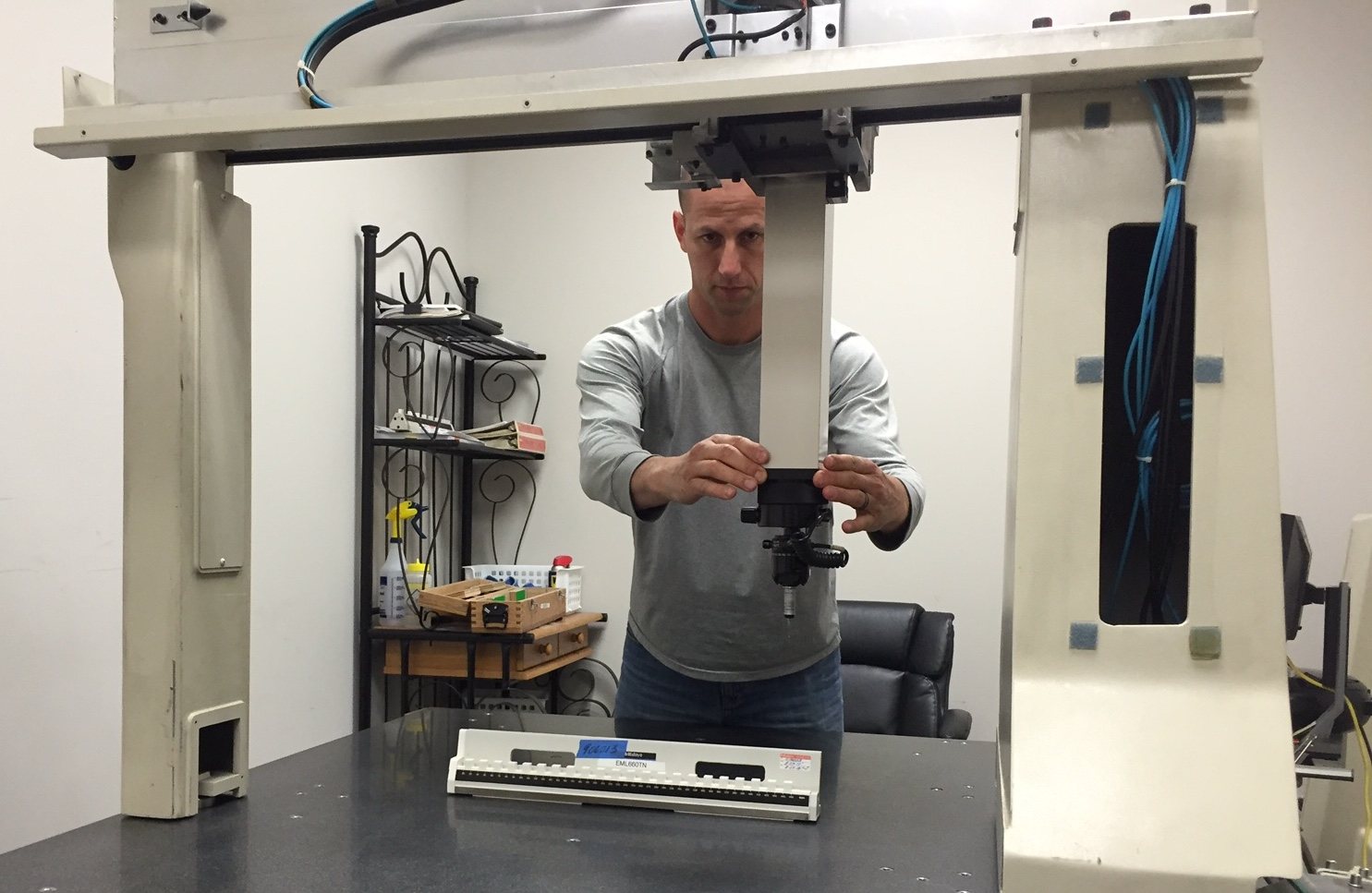

Calibration is the procedure of configuring an tool to offer a result for a pattern inside of an acceptable latitude. It ordinarily includes comparing the measurements from a tool in opposition t a commonly used general. This guarantees accuracy and reliability in measurements and outputs.

The Importance of Calibration in Various Industries

- Manufacturing: In production, precision is non-negotiable. A minor deviation can cause product defects. Healthcare: In healthcare settings, incorrect calibration can pose severe hazards to sufferer safeguard. Laboratory Research: For laboratory researchers, right measurements are imperative for reproducibility.

The Risks of Skipping Calibration

Data Integrity Issues- Uncalibrated methods can generate misleading facts.

- Errors as a result of uncalibrated devices can end in costly reworks or recollects.

- Many industries are discipline to regulations requiring established calibrations; skipping them would cause consequences.

- Failing to supply caliber services or products owing to calibration lapses can tarnish your model's recognition.

- In fields like healthcare or aviation, inaccuracies can jeopardize lives.

Understanding Calibration Standards

What Are Calibration Standards?

Calibration criteria are structured benchmarks used as references all the way through the calibration task. The International Organization for Standardization (ISO) affords instructions that assistance organizations shield consistency throughout measurements.

Types of Calibration Standards

- Primary Standards: Highly right and well-known universally. Secondary Standards: Used for routine exams opposed to popular specifications.

Why Adhere to Calibration Standards?

Adhering to those specifications not simplest enhances dimension accuracy but also promotes confidence with stakeholders through making sure compliance with market norms.

The Calibration Process: Step-via-Step Guide

Identify Equipment Needing Calibration- Regularly evaluate all equipment and establish which wishes calibration established on usage frequency.

- Establish how generally every piece of equipment needs to be calibrated based mostly on its sensitivity and alertness.

- Perform initial exams to judge existing functionality stages beforehand calibration starts offevolved.

- Adjust resources dependent on the findings from initial exams opposed to universal necessities.

- Keep meticulous records of all calibrations performed; that is crucial for audits and compliance tests.

- After variations, conduct observe-up tests to ensure accuracy has been restored.

Common Misconceptions approximately Equipment Calibration

1. "Calibration Isn’t Necessary if Equipment Appears Functional."

Just simply because tools appears operational doesn’t imply it’s featuring true results!

2. "Calibrating Once Is Sufficient."

Routine calibrations need to be component of an ongoing renovation method; one-time calibrations cannot suffice over the years.

3. "Calibration Is Too Expensive."

While there are expenditures associated with calibration, the worth of ignoring it a ways outweighs knowledge losses incurred from defective results or regulatory fines.

The Financial Implications of Neglecting Calibration

Direct Costs vs Indirect Costs

| Cost Type | Description | |------------------|-----------------------------------------------------| | Direct Costs | Immediate expenses regarding recalibration efforts | | Indirect Costs | Long-term financial affects from lost commercial enterprise |

Neglecting ordinary calibrations can lead no longer just quality pressure gauge calibration near me to direct expenditures linked to blunders yet additionally long-time period monetary repercussions stemming from damaged visitor relationships and reputational damage.

How Often Should Calibrations Be Performed?

Factors Influencing Calibration Frequency

Type of Equipment: More sensitive devices require greater well-known tests.

Usage Intensity: High-frequency use will increase wear and tear, necessitating more accepted calibrations.

Environmental Conditions: Temperature fluctuations and humidity phases can influence measurement accuracy—adjust frequency therefore!

Establishing a Calibration Schedule: Best Practices

Creating an robust calibration agenda comprises planning and foresight:

Assess Your Inventory: Identify all methods desiring regular calibration.

Consult Manufacturer Guidelines: Refer to brand pointers for calibration periods.

Implement Tracking Mechanisms: Use software program methods or spreadsheets to avert track of whilst every single piece wishes attention.

Regular Reviews: Continually assess whether your schedule meets operational calls for or calls for adjustment over the years.

The Role of Technology in Modern Calibration

Technology has revolutionized how we process calibration:

- Automated Systems: These streamline techniques via slicing human mistakes all over measurements. Remote Monitoring Tools: They let authentic-time monitoring of instrument performance across areas—no more guesswork! Data Analytics: Analyze trends over time for predictive protection scheduling—continue to be ahead sooner than topics stand up!

Training Employees on Proper Calibration Procedures

A properly-proficient work force is mandatory for effective calibrations:

Initial Training Sessions: Conduct finished onboarding periods outlining approaches evidently.

Ongoing Education: Provide refresher guides incessantly; new applied sciences may possibly replace procedures!

Hands-On Practice: Give people realistic journey under supervision earlier enabling self sustaining obligations—this builds self assurance!

FAQs About Routine Equipment Calibrations

1. What occurs if I bypass calibration?

Skipping calibration can end in erroneous consequences, potentially causing safeguard hazards and regulatory violations.

2. How do I recognize if my appliance desires calibration?

Equipment may still be calibrated step by step per organization standards or after important use/adjustments in ambiance circumstances.

3. Can I practice my personal calibrations?

While some establishments have knowledgeable staff capable of acting undemanding calibrations, using certified gurus guarantees greater reliability and compliance with rules.

4. How long does a normal calibration take?

It varies extensively relying at the apparatus kind yet often levels from a number of hours up to three days which include testing time in a while!

5. Are there certifications needed for technicians acting calibrations?

Yes! Technicians most of the time require explicit practise/certification depending on trade criteria—they desire skills!

6. What documentation is useful submit-calibration?

Maintain special facts including date/time executed, technician in contact, outcomes got pre/publish-calibration along with any adjustments made for the duration of the procedure—it’s very important for audits!

Conclusion

In end, skipping routine accessories calibrations isn’t simply dicy—it’s negative! From compromising info integrity to incurring unnecessary prices down the line—the stakes are excessive whilst it comes down this possible mundane activity! By adhering religiously not best enhances operational effectiveness however safeguards each your supplier’s acceptance & bottom line typical! So don’t reduce corners; prioritize these calibrations like clockwork!

With cautious making plans & execution around these pivotal methods—your group will thrive amid making sure utmost precision & reliability throughout all elements!